Sie müssen eingeloggt sein

Fotos dienen nur zu Informationszwecken.

please use latin characters

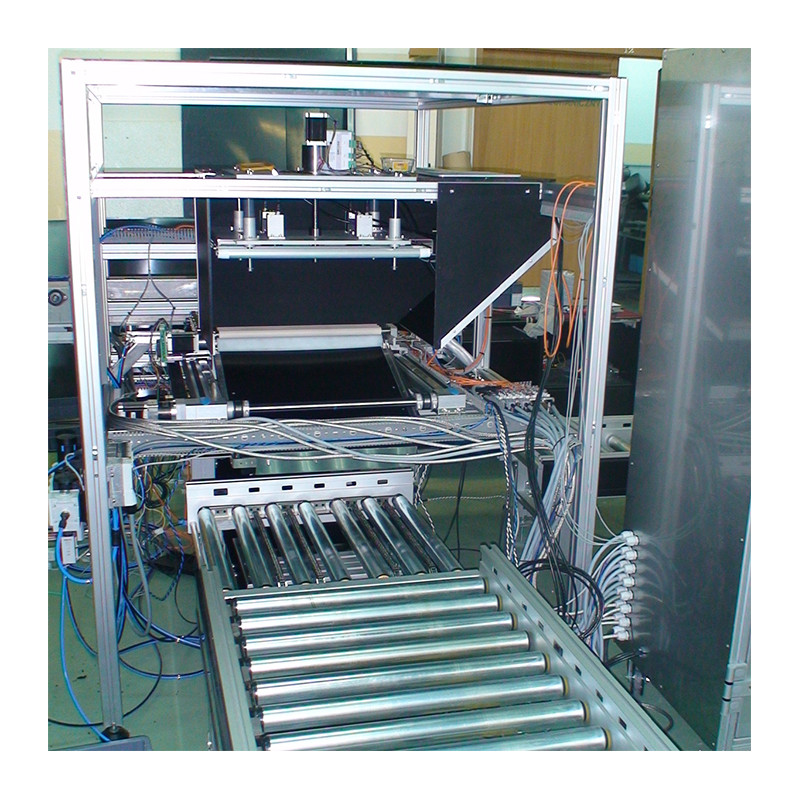

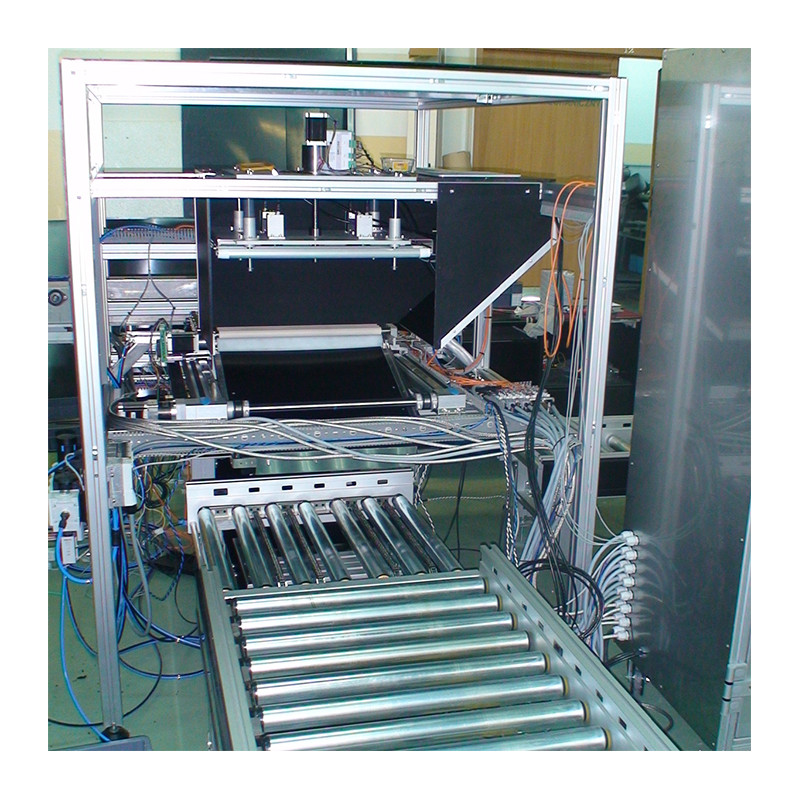

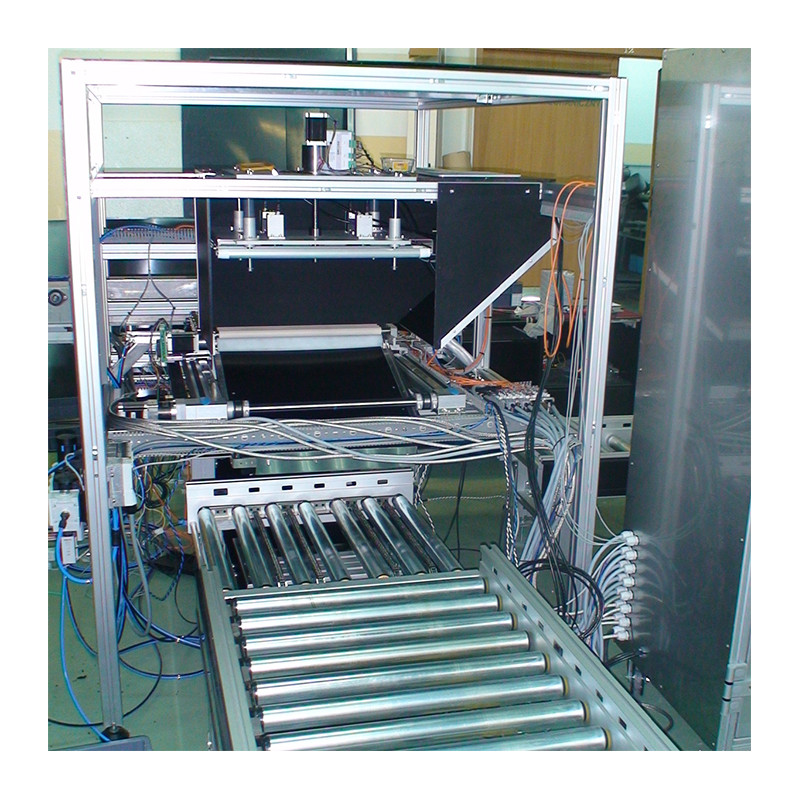

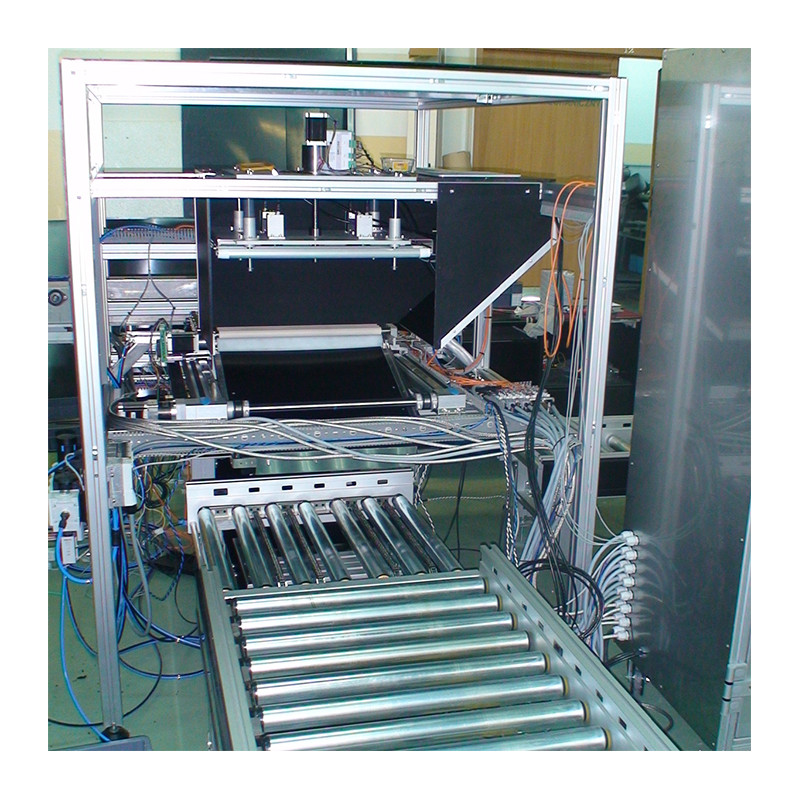

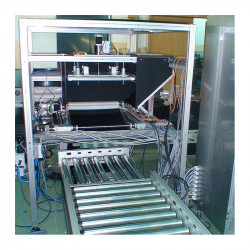

The cardboard labeling stand is used for docketing carton boxes of various sizes - the only limitation is the width of the cardboard that cannot exceed 500 mm. On each cardboard 2 dockets are placed - downloaded online from the Client’s database.

The stand includes:

- two automatic platform jacks (up to the transportation belts height);

- two transportation belts (using two transporters allows automatic cardboard separation);

- roller conveyor used as a buffer;

- printer-docketter for printing and applying dockets;

- computer stand for system control and using client’s database;

- additional printer allowing printing extra labels.

The device allows printing and applying labels on cardboard packages moving on the transporter. Carton boxes are placed on and taken off the transporter manually. On the input and output the device has 2 independent jacks for lifting and lowering the platforms with cardboards. Cardboards are separated on the conveyor belt by the device itself to enable smooth docketing.

The docketter functions as an independent stand for applying labels, where the printing is initiated after reading a barcode that is located on the carton (production label). Printed labels are marked in the device’s system and blocked until the next automatic printing, but the operator can print them again manually in the additional printer for aggregate labels. Labeled cardboards are placed on the roller conveyor that is emptied by the operator.

Interessieren Sie sich für dieses Produkt? Benötigen Sie zusätzliche Informationen oder individuelle Preise?

Sie müssen eingeloggt sein

The cardboard labeling stand is used for docketing carton boxes of various sizes - the only limitation is the width of the cardboard that cannot exceed 500 mm. On each cardboard 2 dockets are placed - downloaded online from the Client’s database.

The stand includes:

- two automatic platform jacks (up to the transportation belts height);

- two transportation belts (using two transporters allows automatic cardboard separation);

- roller conveyor used as a buffer;

- printer-docketter for printing and applying dockets;

- computer stand for system control and using client’s database;

- additional printer allowing printing extra labels.

The device allows printing and applying labels on cardboard packages moving on the transporter. Carton boxes are placed on and taken off the transporter manually. On the input and output the device has 2 independent jacks for lifting and lowering the platforms with cardboards. Cardboards are separated on the conveyor belt by the device itself to enable smooth docketing.

The docketter functions as an independent stand for applying labels, where the printing is initiated after reading a barcode that is located on the carton (production label). Printed labels are marked in the device’s system and blocked until the next automatic printing, but the operator can print them again manually in the additional printer for aggregate labels. Labeled cardboards are placed on the roller conveyor that is emptied by the operator.